The least problematic approach is to have them exit the arm immediately adjacent to the pivot and drop down a central hollow pivot. In all cases the cables that connect to the cartridge provide a challenge in exiting the arm as they generate some degree of resistance and friction. For example the dual arm Dynavector and the tangential arm by ViRa. There are four basic tonearm designs that revolve around the pivoting method used:Ī number of other niche designs do exist each trying to improve on these basic designs. Clearaudio has introduced the use of magnetic bearings that ‘float’ the arm pivot connection with virtually no pivot contact at all. These arms are many times stiffer than any metal equivalent. Some companies like Wilson Beseech have created extremely strong and rigid arms using carbon fiber composite technology. The advantage of this is that, as shown by the GH228, the headshell can be rotated on the armtube a requirement for correct cartridge alignment. In the interests of rigidity some arm manufactures will not provide for the headshell to be easily removed through some form of ‘quick disconnect’.

LOW MASS SME TONEARM SERIES

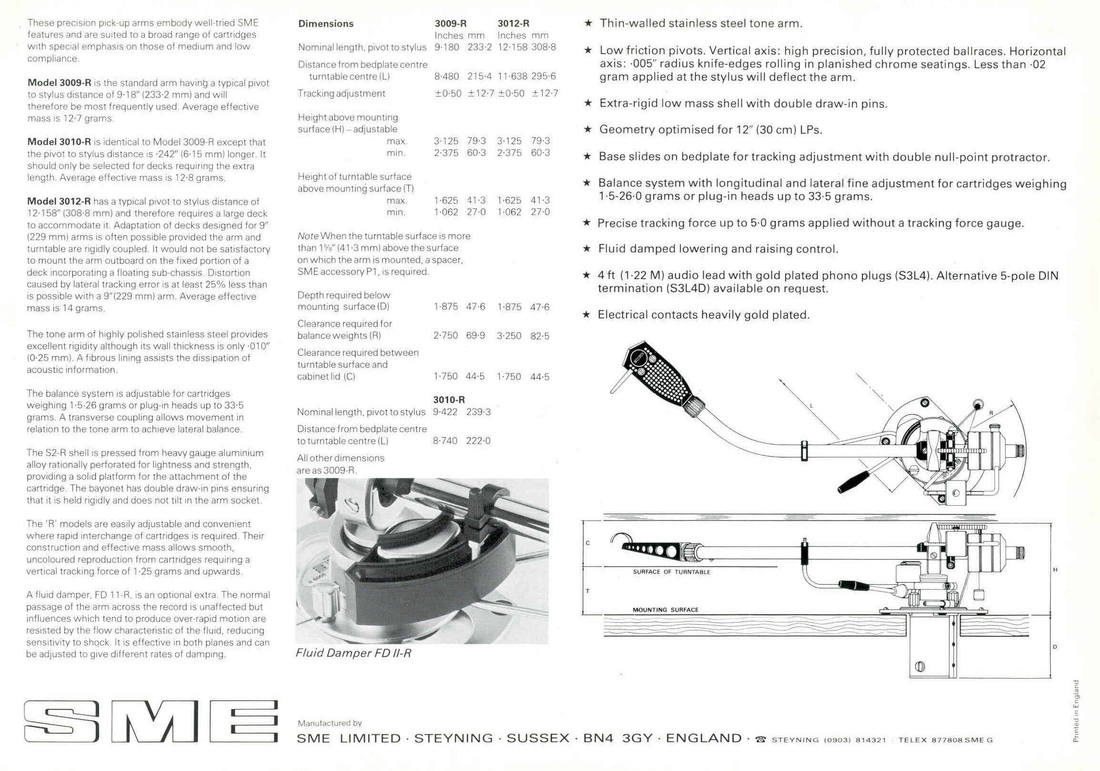

SME Series III – Classic ‘S’ Shaped Arm & Pulley Bias System When the analog master is cut on a lathe its cutting head, that is carried on a ‘sled’, travels in a straight line from the outside to the inside of the disc. Getting all these mechanical issues just right, and a few more, is what makes a great tonearm. These need to be absorbed or damped so as not to ‘color’ the original sound by being reflected back into the cartridge. Remember that the stiffer the arm the more likely it is to resonate or ring when ‘energized’ by the vibrations from the stylus that get transmitted through the cartridge body and into the arm. Armtube materials include, stainless steel, aluminum and carbon fiber.

The armtube has to be stiff, carrying the cartridge at one end and a heavy counterbalance weight at the other and yet light and strong. The pivot, ideally, should provide no resistance to the armtube in any direction as it traverses the records surface.

The rigidity of the armtube is of paramount importance, as is no movement or ‘play’ in the arms pivot point. So any movement of the arm in relation to the traced groove modulation will impact the final electrical signal.

Some of the grooves undulations are minute, being smaller than the wavelength of light. Finally, it contains the cabling that carries the cartridges electrical audio signal to the pre-amplifier. (The bias may be reduced a little as the stylus moves to the records center). While at the same time keeping the downward stylus tracking force and anti-skating bias force constant.

This requires the arm to hold the cartridge at a constant height and angle as it traces the groove towards the records center. The tonearm has to support the cartridge in its correct position over the entire record, while allowing it to move inward to the centre of the record and navigate any vinyl surface imperfections. The arm’s rigidity, mass, bearing & damping all play a role in extracting your cartridges peak performance. The tonearm is of paramount importance in optimizing the performance of your cartridge. The problem for the newcomer is the huge selection and range of costs for these very important vinyl tracing wands. Unless your turntable comes with its manufacturers own tonearm you will need to select an arm to suit the turntable and carry your proposed cartridge. Hadcock GH228 Super – Unipivot Design Introduction

0 kommentar(er)

0 kommentar(er)